new blog

In recent years, carbon-plated running shoes have rapidly risen to prominence in the marathon community, becoming a favorite among many runners. The widespread appeal of these shoes lies in their use of supercritical foam materials for the midsole, which offer exceptional lightweight properties and superior cushioning with rebound performance. Additionally, the carbon plate reinforces the midsole structure, providing arch support and stability, enhancing energy return, and delivering powerful propulsion.

The Importance of Running Shoes in Marathon Sports

In the footwear industry, marathon running has become one of the most popular activities. As a high-intensity sport, marathon running places extremely high demands on the performance of running shoes. Research shows that under specific running conditions, every additional 100g in shoe weight increases the running time for a 3000m distance by 0.78%. Therefore, a lightweight and comfortable running shoe is crucial for enhancing running efficiency.

During a marathon, prolonged running often leads to a decline in energy and reduced muscle control, resulting in decreased joint and muscle stability. This can cause energy transfer inefficiencies during running, leading to energy loss. After long-distance running, significant changes in foot morphology are observed, such as excessive inward rotation of the ankle and a tendency for the arch to lower. If running shoes fail to provide adequate support and timely cushioning, these changes may trigger various sports injuries.

For instance, functional or non-functional overtraining can result in a series of syndromes. When external loads exceed the tissue's recovery capacity and rapid recovery is not achieved, it may lead to tissue overload injuries. To mitigate energy loss caused by inefficient energy transfer and alleviate fatigue from marathon running, it is essential to incorporate sufficient support and cushioning mechanisms, particularly in the shoe sole, to promote foot function recovery throughout the shoe's design.

Two Core Factors of Carbon-Plated Running Shoes

1. Carbon Plate

The carbon plate is a high-strength, lightweight carbon fiber composite material, typically made by combining carbon fiber strands with epoxy resin. It is usually embedded in the midsole of running shoes. Its primary function is to utilize the lever principle, storing the impact force generated when a runner lands and releasing it during the push-off phase, thereby creating additional propulsion.

Carbon plate technology can reduce energy loss with each step for runners, helping maintain running efficiency, especially during long-duration exercise. Research shows that running shoes with embedded carbon fiber plates can reduce running energy consumption by about 4%, making them regarded as "cutting-edge technology" for improving performance. Carbon plate running shoes can be divided into three types: "support type," "stabilizing type," and "propulsion type."

Support Type: These shoes typically have a small carbon plate area, or the area of focus is around the arch. The carbon plate absorbs a significant amount of downward force on the arch, providing arch support and reducing pressure on it.

Stabilizing Type: These shoes are developed based on the "support type," with a larger carbon plate area. The carbon plate typically forms an "X" or "Y" shape in the center of the shoe, extending forward and backward. The primary function is to provide "support" and "stability."

Propulsion Type (Shovel Type): These shoes have a whole piece of carbon plate design, without perforation, offering the well-known benefit of "performance enhancement" associated with carbon plate shoes.

Despite the many advantages of carbon plate running shoes, they are not suitable for all runners. The rigidity and structural characteristics of the carbon plate make them more suitable for runners with strong running techniques and power. If a runner lacks sufficient strength and technique, they may feel discomfort or increase the risk of injury. Runners with different needs should choose the appropriate type of carbon plate:

- Support Type: Best for high-mileage training, providing additional arch support and stability.

- Stabilizing Type: Suitable for intermediate-level competitive runners, helping to better utilize the carbon plate's performance to improve running economy.

- Propulsion Type: Specifically designed for performance-focused runners, maximizing the propulsion effect to increase speed.

Of course, it is important to objectively recognize that while carbon plates are powerful, in running shoes, they need to be paired with high-performance foam midsoles to achieve their full potential. The two complement each other. The carbon plate is generally placed above, below, or embedded within the midsole.

2. Midsole Technology

2.1 PEBA

In recent years, PEBA (polyether block amide) elastomer has gradually become one of the most powerful materials for running shoe midsoles. It is a block copolymer made from rigid polyamide segments and soft polyether segments. The combination of the rigidity of polyamide and the elasticity of polyether allows the PEBA elastomer to achieve extremely high energy recovery during repeated bending, thus reducing energy loss to a very low level.

Nike's ZoomX midsole technology is made from PEBAX supercritical foam and boasts an energy return rate of up to 85%. This innovation has caused a huge sensation in the running shoe industry and is considered one of the top midsole materials. Running shoes equipped with ZoomX, such as the Alphafly and Vaporfly series, have become the go-to footwear for long-distance running legends like Eliud Kipchoge and Haile Gebrselassie.

2.2 EVA

EVA (Ethylene Vinyl Acetate) is one of the earliest foam materials used in shoe midsoles. It is lightweight, easy to process, and the rebound rate of pure EVA foam generally ranges from 40% to 45%. Due to its cost advantage, EVA foam material has been the primary material choice for mainstream sports shoes for a long time.

2.3 ETPU

ETPU (Expanded Thermoplastic Polyurethane) is a type of thermoplastic elastomer made from a block copolymer consisting of diisocyanates, chain extenders, and polyols. The soft segments made from polyols exhibit flexibility and toughness, while the diisocyanates act as hard segments, providing hardness and rigidity. After crystallizing, the hard segments form physical crosslinking points, which gives TPU its high elasticity. Therefore, TPU has notable advantages such as high tensile strength, large elongation, and low permanent deformation under long-term compression.

When TPU is foamed, it becomes ETPU, which has a popcorn-like texture and exhibits excellent rebound and deformation recovery abilities. The ball rebound value of its foam is typically as high as 60%. In 2013, Adidas introduced the Boost midsole technology, centered around "popcorn" (ETPU), and used it in the EnergyBOOST running shoe. In 2015, Adidas launched the UltraBoost midsole foam technology and the UltraBoost series running shoes, which created a huge sensation in the running shoe industry. In July of this year, Adidas launched the latest Ultraboost 5 and Ultraboost 5X, with the Ultraboost 5 midsole featuring Adidas' latest LIGHT BOOST technology, which reduces weight while providing all the advantages of standard BOOST foam.

2.4 TPEE

TPEE (Thermoplastic Polyester Elastomer) is essentially a block copolymer made from polyester as the hard segment and polyether/polyester as the soft segment. The most common type of TPEE is the polyether ester type, with PBT (Polybutylene Terephthalate) and PTMG (PolyTetraHydroFuran Glycol) as the main structural components.

The high rebound elasticity, fatigue resistance, and low-temperature flexibility of TPEE make it an ideal material for outdoor sports products. In early 2022, Adidas launched the Adizero ADIOS Pro 2, equipped with its Lightstrike Pro technology. This material is made from TPEE supercritical foam, offering a cushioning and rebound experience comparable to ZoomX, and it achieved excellent results in the ROAD TO RECORDS challenge.

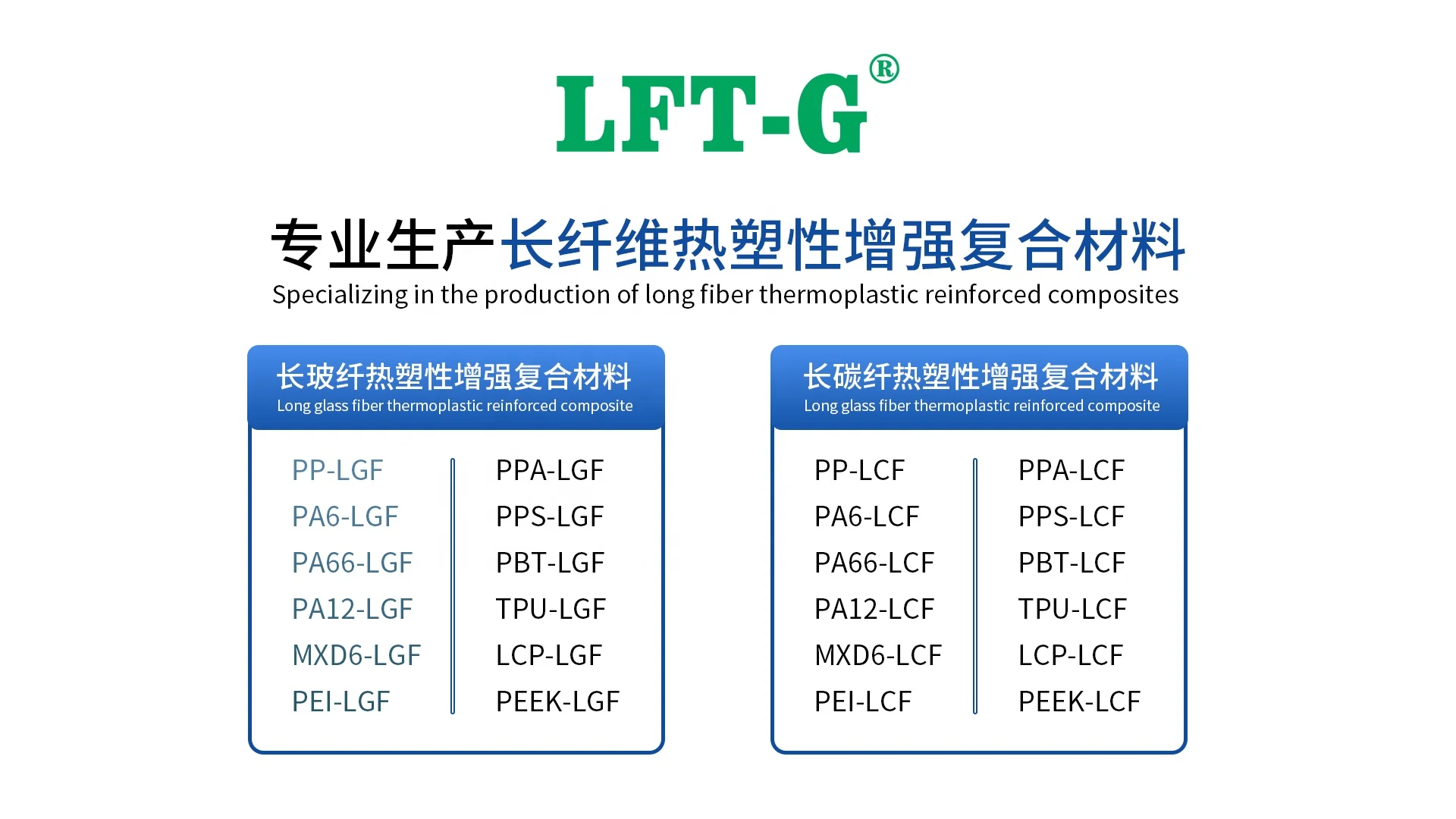

Xiamen LFT offers a variety of carbon fiber composites for carbon plate production in shoe soles.

You can contact us to receive free technical support.